Photovoltaic Mounting Structures

At Glif – steel profiles, we combine our extensive experience in steel profile manufacturing with modern solutions for the renewable energy sector. Our photovoltaic mounting structures are robust, durable, and precision-engineered systems that ensure the stability and safety of photovoltaic installations under all conditions. By using top-quality materials and innovative production technologies, we deliver solutions tailored to the individual needs of our customers.

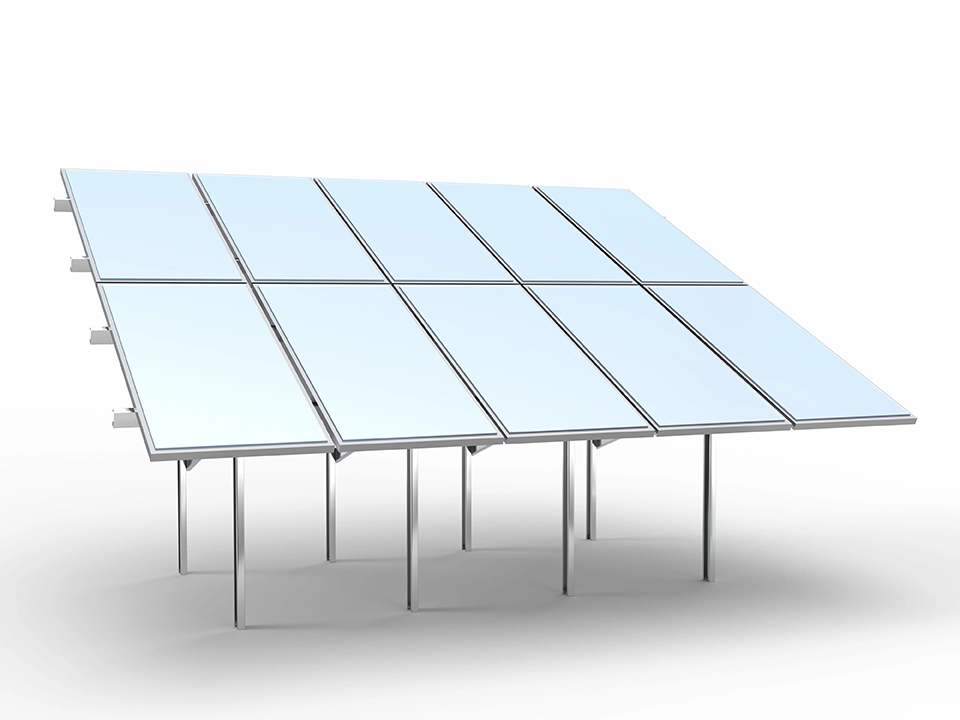

Monofacial

A traditional, single-sided mounting structure for photovoltaic panels designed to generate power from the sun-facing side. Our structure is compatible with conventional photovoltaic panels.

Advantages: lower initial costs, durable construction, Magnelis® coating.

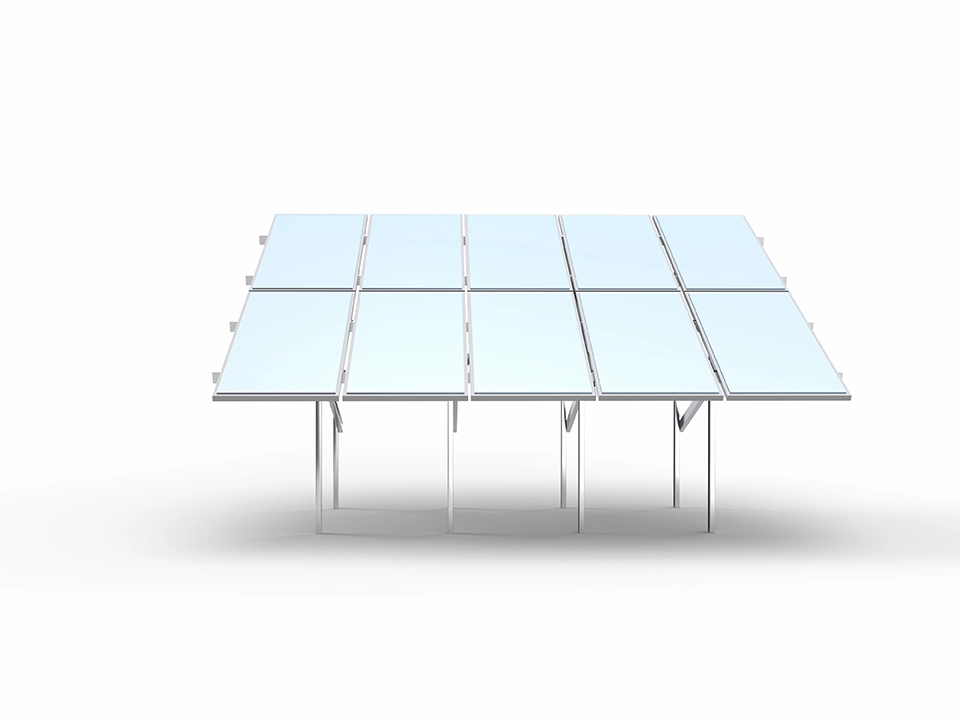

Bifacial

Bifacial structures are designed for photovoltaic panels that capture sunlight from both sides (semi-transparent modules). Their key advantage is the ability to generate energy from light reflected off the ground, which can increase power output by up to 30%.

Advantages: increased rear-side energy gain, modern design, durable construction, Magnelis® coating, suitable for open areas with light-reflective surfaces.

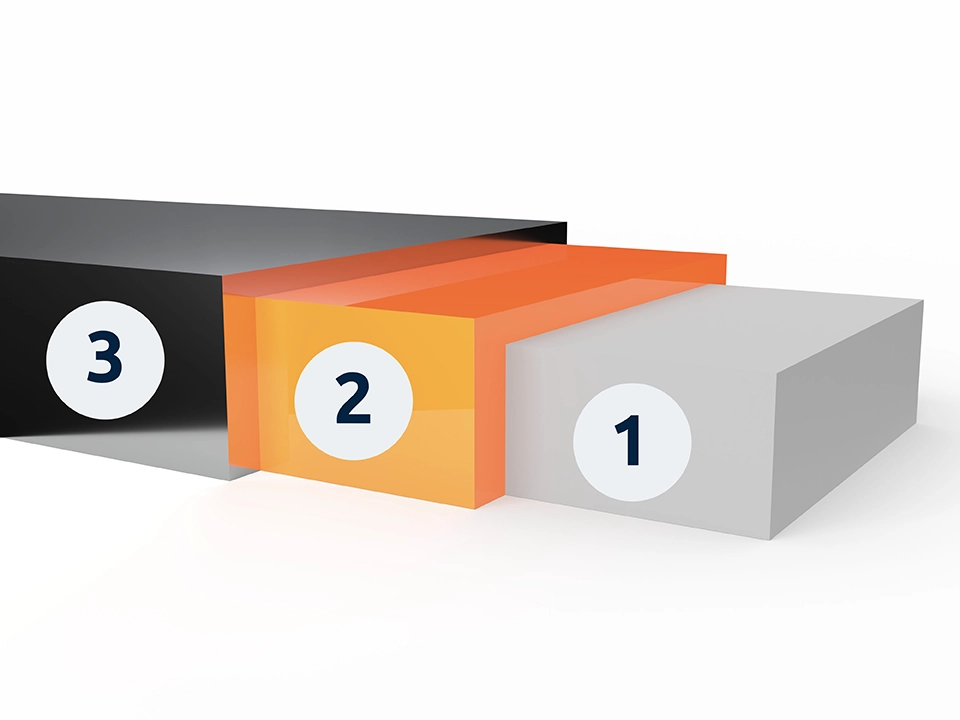

Magnelis

Magnelis® is an innovative metallic coating (zinc, 3.5% aluminum, 3% magnesium) that provides exceptional corrosion resistance, significantly outperforming traditional zinc coatings. It performs excellently in harsh environmental conditions such as high humidity or saline environments. Thanks to its self-healing properties and long-lasting durability, Magnelis® is an ideal solution for photovoltaic mounting structures, ensuring extended service life and low maintenance costs.

Use of Magnelis in our profiles (diagram):

- Steel core

- Magnelis coating

- Oiling / e-passivation

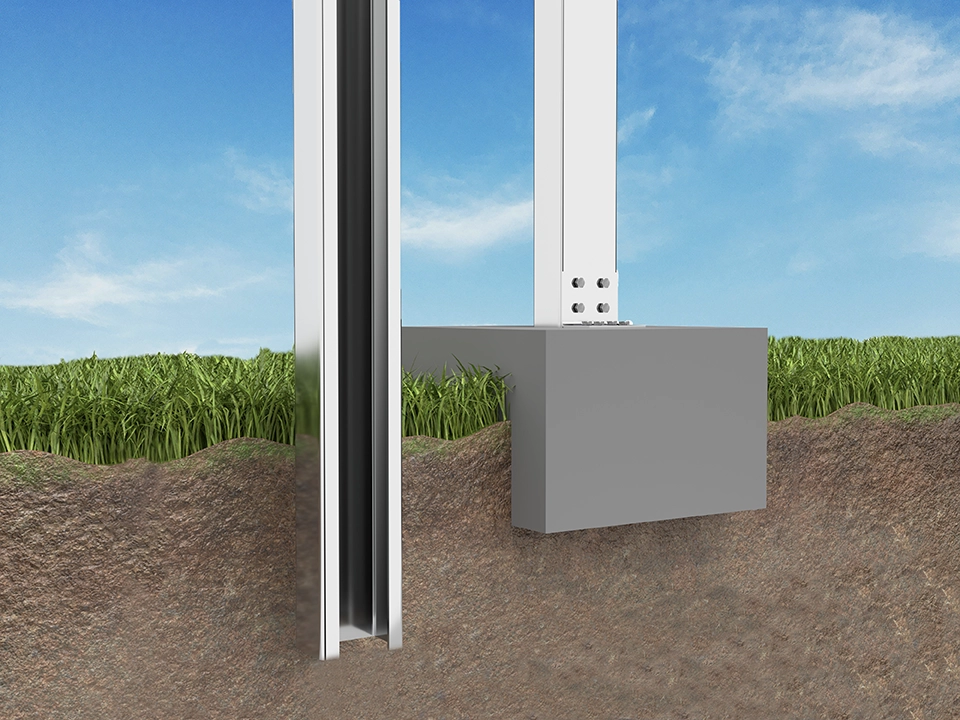

Structural assembly

The installation of photovoltaic mounting structures is a key stage that ensures the stability and durability of the panels. Two mounting methods are used: driving the profiles into the ground or installation on a concrete foundation.

Driving profiles into the ground

With stable ground conditions, such as compact soils, steel profiles are driven to a depth of approx. 1.5 m. This ensures resistance to wind and snow loads, while the installation process is fast and cost-effective. This method minimizes ground disturbance and allows for rapid completion of the installation.

Mounting on concrete

In the case of unstable soils (e.g. sandy or waterlogged ground), concrete foundations are used. This provides the highest level of stability but requires greater time and financial investment. The structure is mounted on foundation blocks or strip footings, ensuring resistance to changing weather conditions

Available Modules

Our capabilities — your choice. We offer mounting structures designed to accommodate from 4 up to 32 photovoltaic panels. The panels can be arranged in either vertical or horizontal orientation. We approach every order individually, providing solutions tailored to specific project requirements.

We Invite You to Cooperate!

As an experienced steel profile manufacturer, we offer the highest quality, precision, and timely deliveries. We are looking for business partners who value reliability and trustworthiness. Together, we can create durable and modern solutions for many industries!